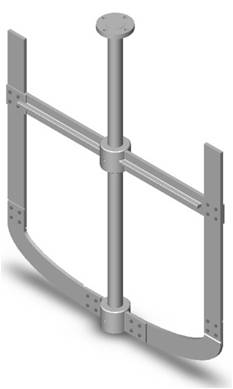

Anchor Impellers

Low Clearance Impellers

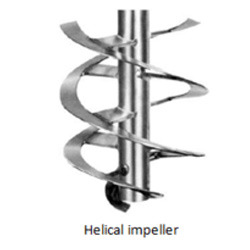

- The anchor impeller and the helical impeller are the two commonly used close clearance impellers.

- The diameter of the close clearance impellers is typically 90 – 95 percent of the inside diameter of the vessel.

- The shear near the vessel wall reduces the build up of stagnant material and promotes treat transfer.

- The anchor impeller is a radial flow impeller

- Helical impeller provides axial discharge of material by producing strong top to bottom motion

- Anchor blades may be used in combination with other types of impellers

Related Links

- Marine Propeller - In a theoretical environment, one full revolution would move the liquid longitudinally a fixed distance depending upon the of inclination of propeller blades…Read more

- Pitched Blade Turbine – Impeller Diameter – 450 mm to 3000 mm,Hub with even number of blades are mounted at an angle of 10° to 90° with respect to the horizontal…Read more

- Hydrofoil Impellers - High efficiency impellers designed to maximize fluid flow and minimize shear rate. 3 or 4 tapering twisted blades…Read more

- Radial Flow Impeller – The impeller blade is parallel to the axis of the impeller,Radial flow impeller discharges flow along the impeller radius…Read more

- Rushton Turbine - The Rushton turbine is a disk type (six blade turbine) radial flow impeller,The diameter of the disk ranges from 66 to 75 percent of the internal vessel diameter…Read more

- Open Blade Turbine – In open blade turbine, the blades are directly mounted on the hub…Read more

- High Shear Impeller - Used for application such as grinding, dispersing pigments and making emulsions…Read more

Social Network Links