Vessel:

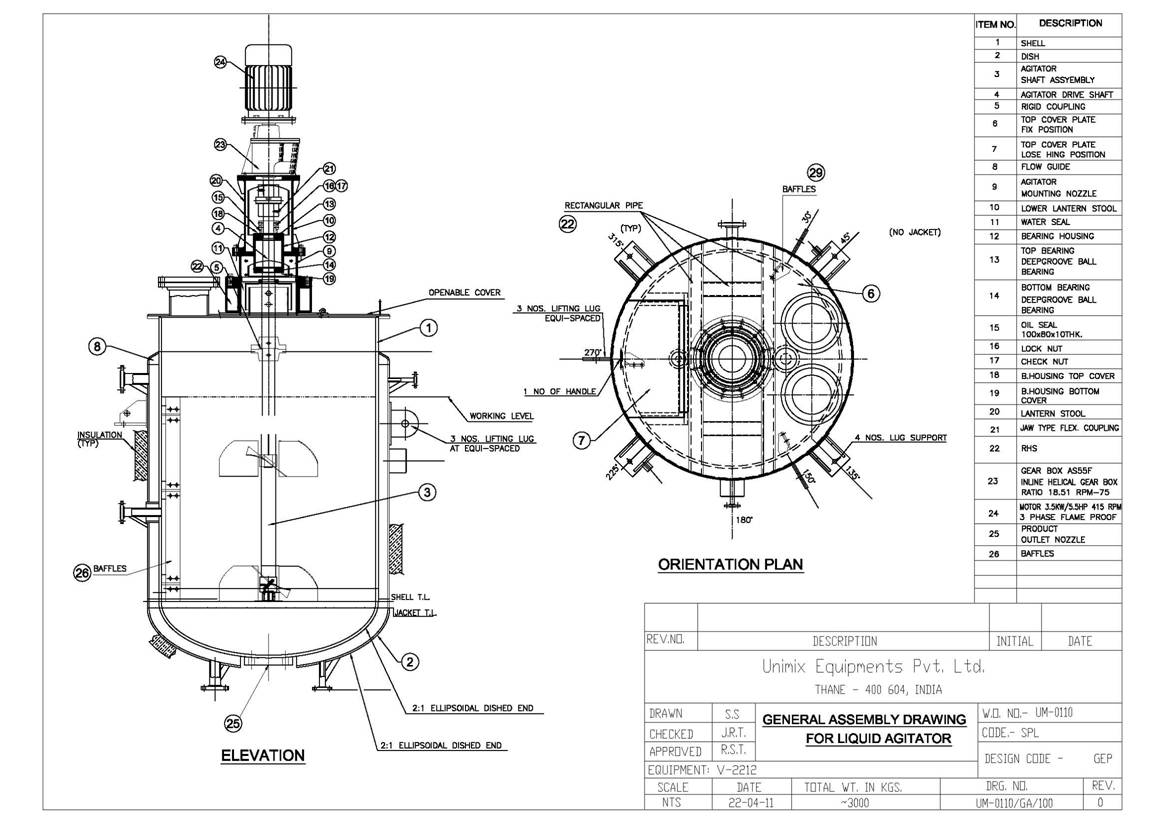

- Vertical cylindrical vessel with a liquid height which is equal to the tank diameter.

- The vessel top and bottom may be provided with flat or dished ends.

- Dished bottom heads can be 2:1 ellipsoidal, torispherical, hemispherical or conical.

- Nozzles – Agitator mounting, feeding, measurement instruments, manhole, material discharge

- Design for the operating temperature and pressure conditions.

- The thickness of the vessel shell and dished ends should be calculated using the relevant pressure vessel design codes.

Baffle:

- Baffles are installed on agitator vessels to produce a flow pattern conducive to good mixing and to prevent vortex formation.

- In standard agitation equipment configurations, 4 vertical baffles are provided each of which has a width of 1/10th or 1/12th of the tank diameter.

- Baffles are generally offset from the vessel wall by a distance equal to 1/3rd to 1/6th width of the baffle.

- Baffles increase the power consumption of the mixer but in turn improve the process performance.

Draft Tubes:

- Draft tube is a cylindrical duct slightly larger than the impeller diameter and is positioned around the impeller.

- Used with axial impellers to direct the suction and discharge flows.

- The impeller draft tube system acts as a low efficiency axial flow pump.

- The top to bottom circulation flow is of significance for flow controlled process, suspension of solids and for dispersion of gases.

- They are particularly useful in tall vessels having high ratio of height to diameter.

Heat Transfer Surfaces:

- Heat transfer surfaces are provided for applications which require heating or cooling of process.

- Heat transfer for an agitated vessel is dependent on the following.

- Overall heat transfer coefficient.

- Surface area for heat transfer.

- Temperature difference between the heat transfer fluid and the process fluid.

- The heat transfer co-efficiencies can be estimated using established corrections.

- The turbulence created by the action of the impeller improves the heat transfer coefficient.

Impellers

Impeller designs may also be classified based on the amount of shear that they produce. |

Axial flow impellers

Radial flow impellers

Low clearance impellers

|

Related Links

- Marine Propeller - In a theoretical environment, one full revolution would move the liquid longitudinally a fixed distance depending upon the of inclination of propeller blades…Read more

- Pitched Blade Turbine – Impeller Diameter – 450 mm to 3000 mm,Hub with even number of blades are mounted at an angle of 10° to 90° with respect to the horizontal…Read more

- Hydrofoil Impellers - High efficiency impellers designed to maximize fluid flow and minimize shear rate. 3 or 4 tapering twisted blades…Read more

- Radial Flow Impeller – The impeller blade is parallel to the axis of the impeller,Radial flow impeller discharges flow along the impeller radius…Read more

- Rushton Turbine - The Rushton turbine is a disk type (six blade turbine) radial flow impeller,The diameter of the disk ranges from 66 to 75 percent of the internal vessel diameter…Read more

- Open Blade Turbine – In open blade turbine, the blades are directly mounted on the hub…Read more

- Anchor Impeller – The Low Clearance Impellers:Anchor Impeller and the helical impeller are the two commonly used close clearance impellers…Read more

- High Shear Impeller – Used for application such as grinding, dispersing pigments and making emulsions…Read more